Powder Baking Oven Diesel Fired

Price 285000.00 INR/ Set

Powder Baking Oven Diesel Fired Specification

- Condition

- New

- Accuracy

- 2C

- Heating Method

- Direct Diesel Fired

- Heating Capacity

- Up to 200C

- Power Source

- Diesel

- Control Mode

- Digital temperature controller

- Type

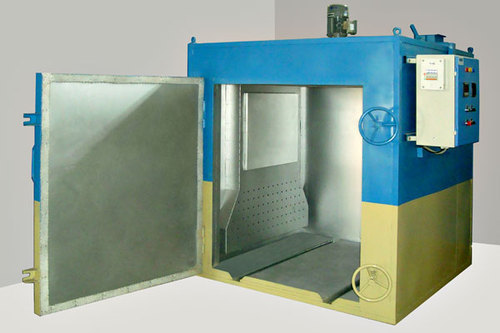

- Industrial Powder Curing/Baking Oven

- Model

- Diesel Fired Powder Baking Oven

- Internal Size

- 1800 mm x 1400 mm x 1700 mm

- External Size

- 2100 mm x 1700 mm x 1930 mm

- Volume

- Approx. 4.3 m

- Air Flow

- Uniform, Power Driven Fan Circulation

- Temperature Range

- 50C to 250C

- Material

- Mild Steel (MS) with high-temperature paint

- Dimension (L*W*H)

- 2100 mm x 1700 mm x 1930 mm

- Power

- 6.5 kW

- Voltage

- 415 V

- Surface Finish

- Powder Coated

- Safety Features

- Over-temperature protection, Flame failure alarm

- Heating Time

- 20-35 minutes to maximum temperature

- Usage/Application

- Powder coating curing, paint baking, metal finishing

- Installation

- Floor-mounted, ready to install

- Exhaust System

- Adjustable exhaust damper for fumes and moisture release

- Insulation Thickness

- 120 mm high-density mineral wool

- Door Type

- Double leaf, front opening insulated doors

- Fuel Consumption

- 1.5 - 2.0 Litre/hour (average, depends on temperature)

- Thermostat

- Digital, adjustable set-point with display

- Chamber Construction

- Double wall, fully insulated for energy efficiency

Powder Baking Oven Diesel Fired Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 1 Months

About Powder Baking Oven Diesel Fired

SPECIFICATION

| Max Temperature | 100-200 deg. Celsius |

| Material To Be Coated | Steel |

| Type | Cabinet Ovens |

| Door Type | Double Door |

| Automation Grade | Semi-Automatic |

| Brand | BSJS |

| Power Source | Diesel |

| Display | Digital |

| Material | Mild Steel |

| Frequency | 50Hz |

| Model | Internal Dimensions (WXDXH Feet) | Fuel | Blower Motor H.P |

| BSJS - 456 | 4 X 5 X 6 | HSD/LPG | 1.5 HP |

| BSJS - 457 | 4 X 5 X 7 | HSD/LPG | 1.5 HP |

| BSJS - 458 | 4 X 5 X 8 | HSD/LPG | 2 HP |

| BSJS - 558 | 4 X 5 X 8 | HSD/LPG | 2 HP |

| BSJS - 4510 | 4 X 5 X 10 | HSD/LPG | 3 HP |

| BSJS - 5510 | 5 X 5 X 10 | HSD/LPG | 3 HP |

| BSJS - 4512 | 4 X 5 X 12 | HSD/LPG | 2X2 HP |

| BSJS - 4516 | 4 X 5 X 16 | HSD/LPG | 2X3 HP |

| BSJS - 4518 | 4 X 5 X 18 | HSD/LPG | 2X3 HP |

Energy-Efficient Construction

This oven boasts a double-wall, fully insulated chamber lined with high-density mineral wool. The robust mild steel exterior is finished with high-temperature powder coating, ensuring durability. Thick insulation reduces heat loss, saving on fuel consumption and maximizing operational efficiency in any industrial setting.

Digital Precision and Safety

Achieve optimal results with the digital thermostat, offering adjustable set-points and real-time temperature displays. Safety features include over-temperature protection and a flame failure alarm, making it reliable for continuous industrial operation. The systems accuracy of 2C ensures consistent, high-quality finishes in every batch.

Versatile Installation and Usage

Designed as a floor-mounted solution, the oven is ready for quick installation. The adjustable exhaust damper efficiently manages fumes and moisture during operation. Suitable for powder coating, paint baking, and metal finishing, the spacious interior (1800 x 1400 x 1700 mm) handles diverse product sizes, enhancing productivity for manufacturers and suppliers.

FAQs of Powder Baking Oven Diesel Fired:

Q: How does the Diesel Fired Powder Baking Oven ensure efficient heat retention?

A: This oven features double-wall construction with 120 mm high-density mineral wool insulation, significantly reducing heat loss. The robust design ensures energy efficiency and consistent temperature maintenance during the baking or curing process.Q: What process is involved in operating the oven for powder coating curing?

A: Start by loading the products onto the racks inside the chamber, close the double-leaf doors, and set the desired temperature using the digital temperature controller. The diesel burner heats the oven, and the power-driven fan ensures uniform air flow, while the adjustable exhaust damper manages fumes and moisture release during curing.Q: When should the exhaust damper be adjusted during operation?

A: The adjustable exhaust damper should be set according to the amount of moisture and fumes generated during baking or curing. Proper adjustment ensures efficient removal, preserves air quality within the workspace, and helps achieve uniform finishes.Q: Where is the Diesel Fired Powder Baking Oven best utilized?

A: This oven is ideal for industrial environments where powder coating, paint curing, or metal finishing are required. Its robust build and high capacity are suited for factories, manufacturing units, and finishing workshops across India.Q: What are the main benefits of using a diesel-fired oven over electric models?

A: Diesel-fired ovens typically heat up faster and can be more cost-effective to operate in regions where diesel is readily available or where electrical supply may be limited or expensive. They also reach higher temperatures efficiently, making them suitable for heavy-duty industrial usage.Q: How does the oven maintain temperature accuracy and safety during usage?

A: The digital thermostat provides precise control with an accuracy of 2C, while integrated over-temperature protection and flame failure alarms safeguard the equipment and operators, ensuring reliable and safe operation throughout the heating cycle.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Industrial Oven Category

Powder Baking Oven

Price 285000.00 INR / Set

Minimum Order Quantity : 1 Piece

Material : Mild Steel with Powder Coating

Voltage : 415 V AC

Condition : New

Power Source : Electric

Gas Oven

Price 285000.00 INR / Set

Minimum Order Quantity : 1 Piece

Material : Stainless Steel (Internal & External)

Voltage : 220 V

Condition : New

Power Source : Other, Natural Gas / LPG

Varnish Drying Oven

Price 285000.00 INR / Set

Minimum Order Quantity : 1 Piece

Material : Mild Steel, Powder Coated

Voltage : 380V / 50Hz

Condition : New

Power Source : Electric

Industrial Heating Oven

Price 450000.0 INR / Set

Minimum Order Quantity : 1 Piece

Material : Mild Steel with Powder Coated Finish

Voltage : 380 V / 415 V, 3 Phase

Condition : New

Power Source : Electric

|

B.S. JAGDEV & SONS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry